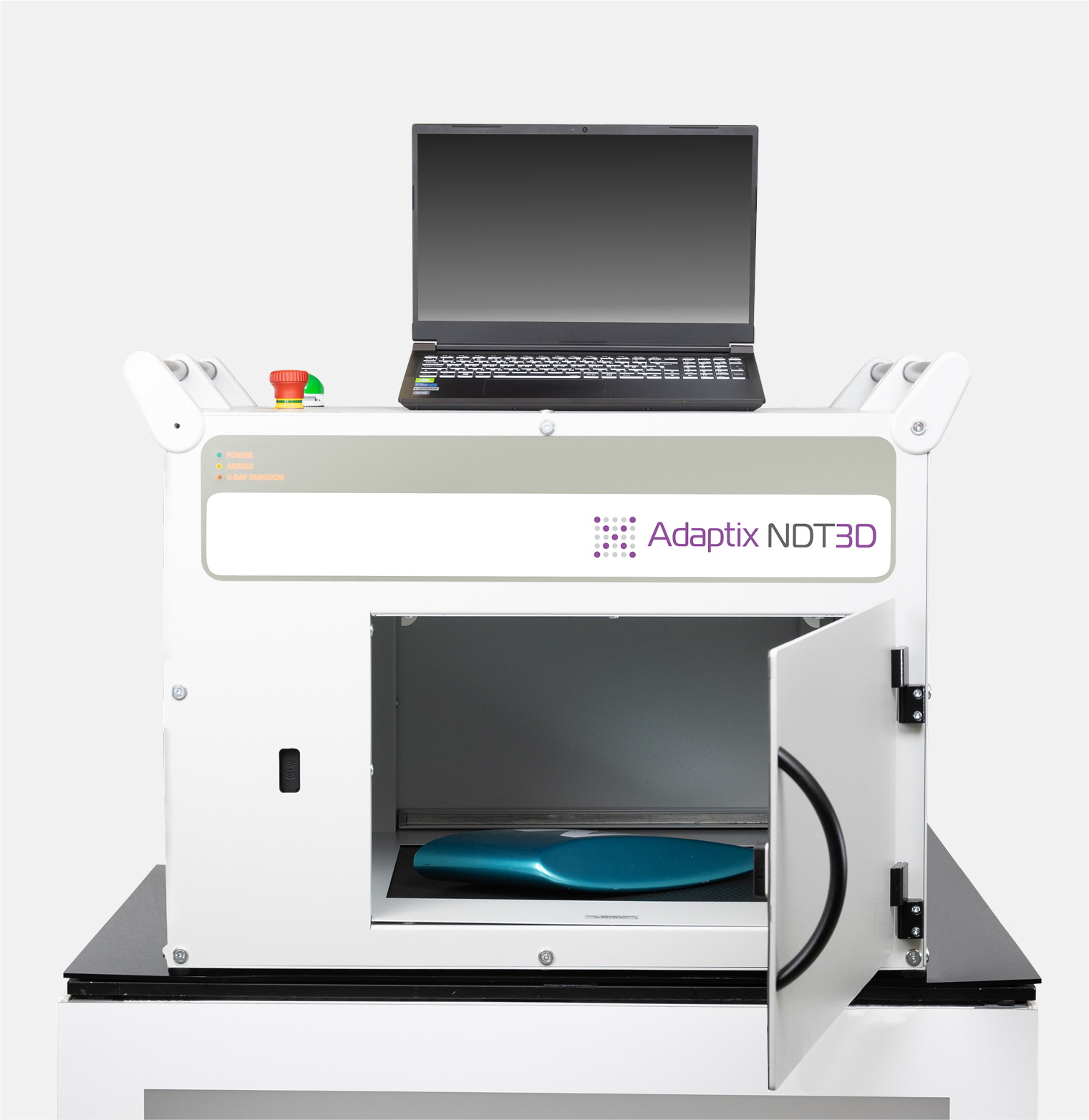

Adaptix NDT3D.

Transforming NDT with 3D X-ray imaging.

How it works.

Adaptix have developed Digital Tomosynthesis technology which allows imaging of parts in a fraction of the time of traditional 3D imaging (CT).

This is possible through the use of a series of low dose 2D X-ray projections which are taken from different positions, then reconstructed using specialized software algorithms to combine into a stack of slices.

These slices are presented in a scrollable stack which the NDT technician can then scroll through (like the pages of a book) and view features within the volume of the part. This technology is fast and accurate, providing results within minutes.

How Our Technology is Transforming NDT.

Transforming Inspection Economics.

- Compressing inspection cycles

- Enhancing risk management

- Reducing inventory holding

- Reducing operating costs

Transforming Processes.

- Deployable 3D X-ray for manufacturing and maintenance

- Finding faults/rework ~65% sooner in process

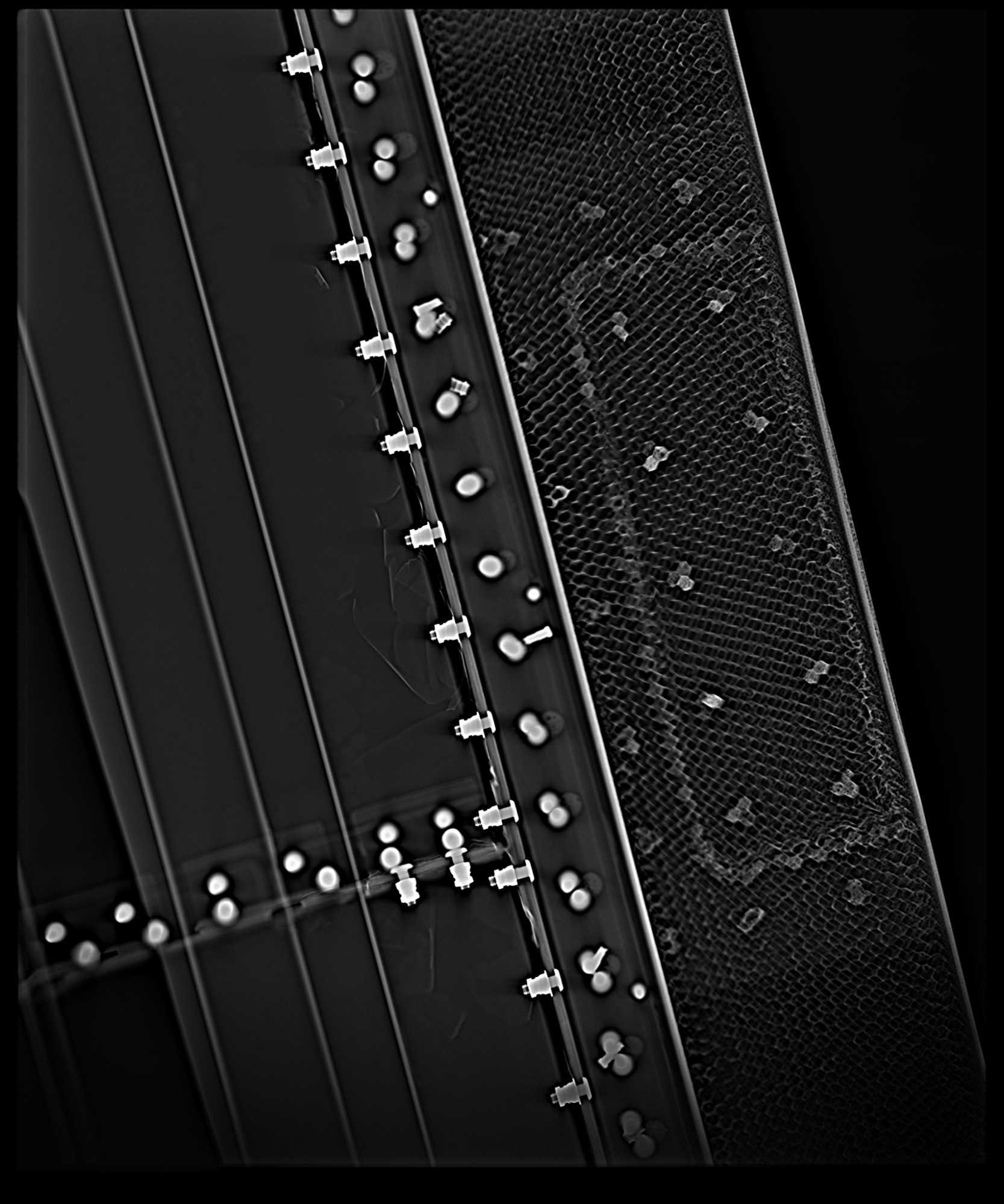

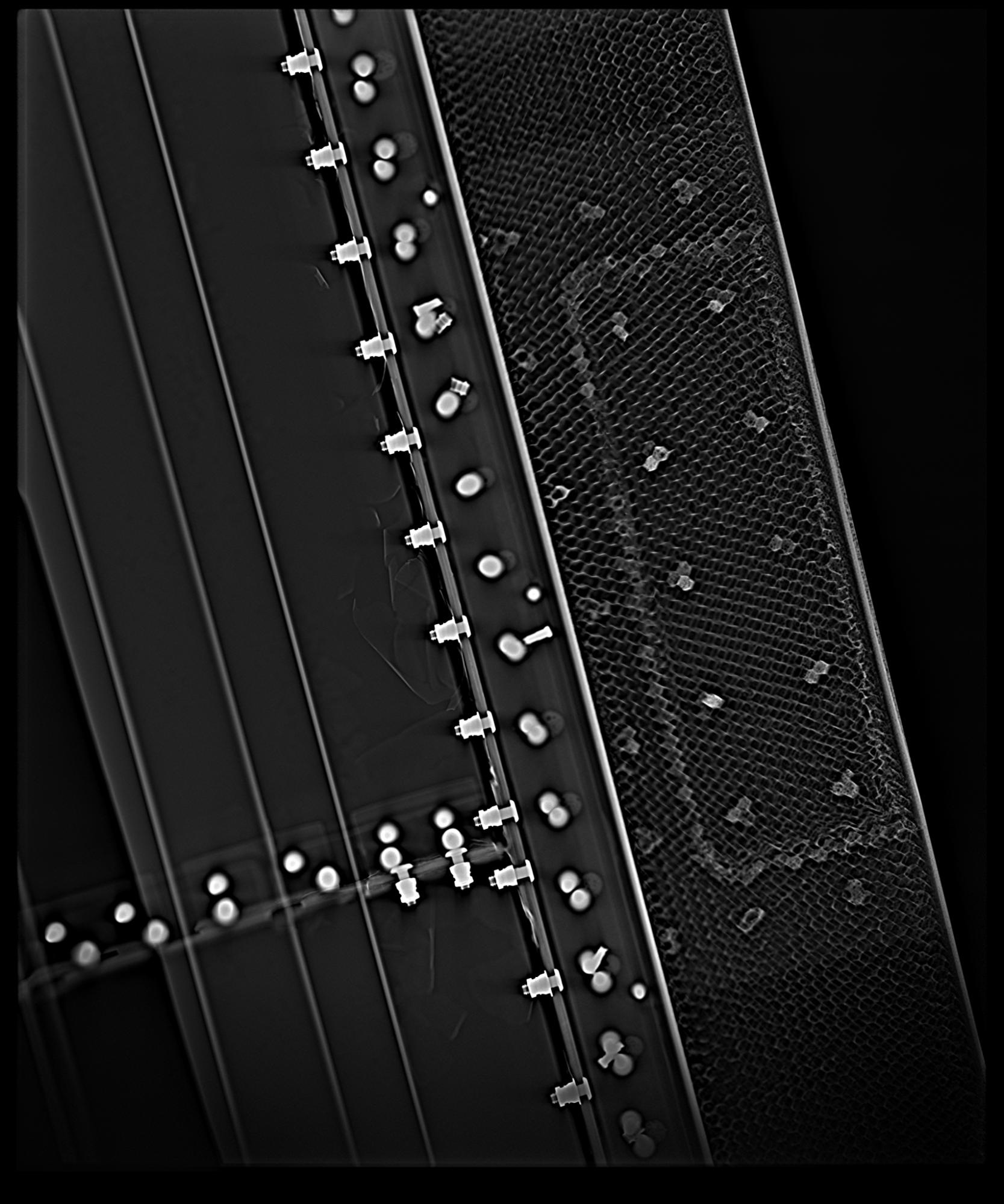

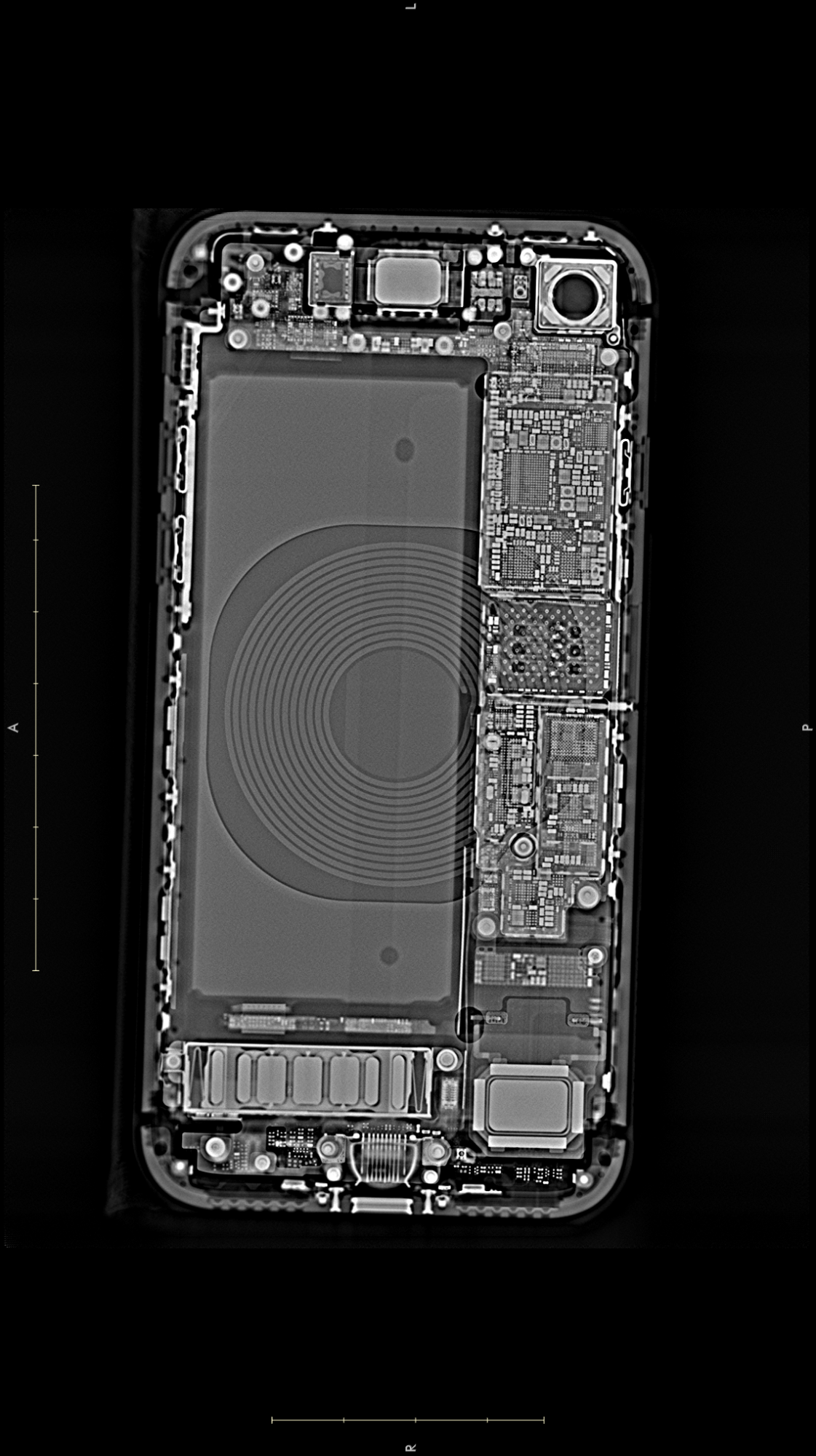

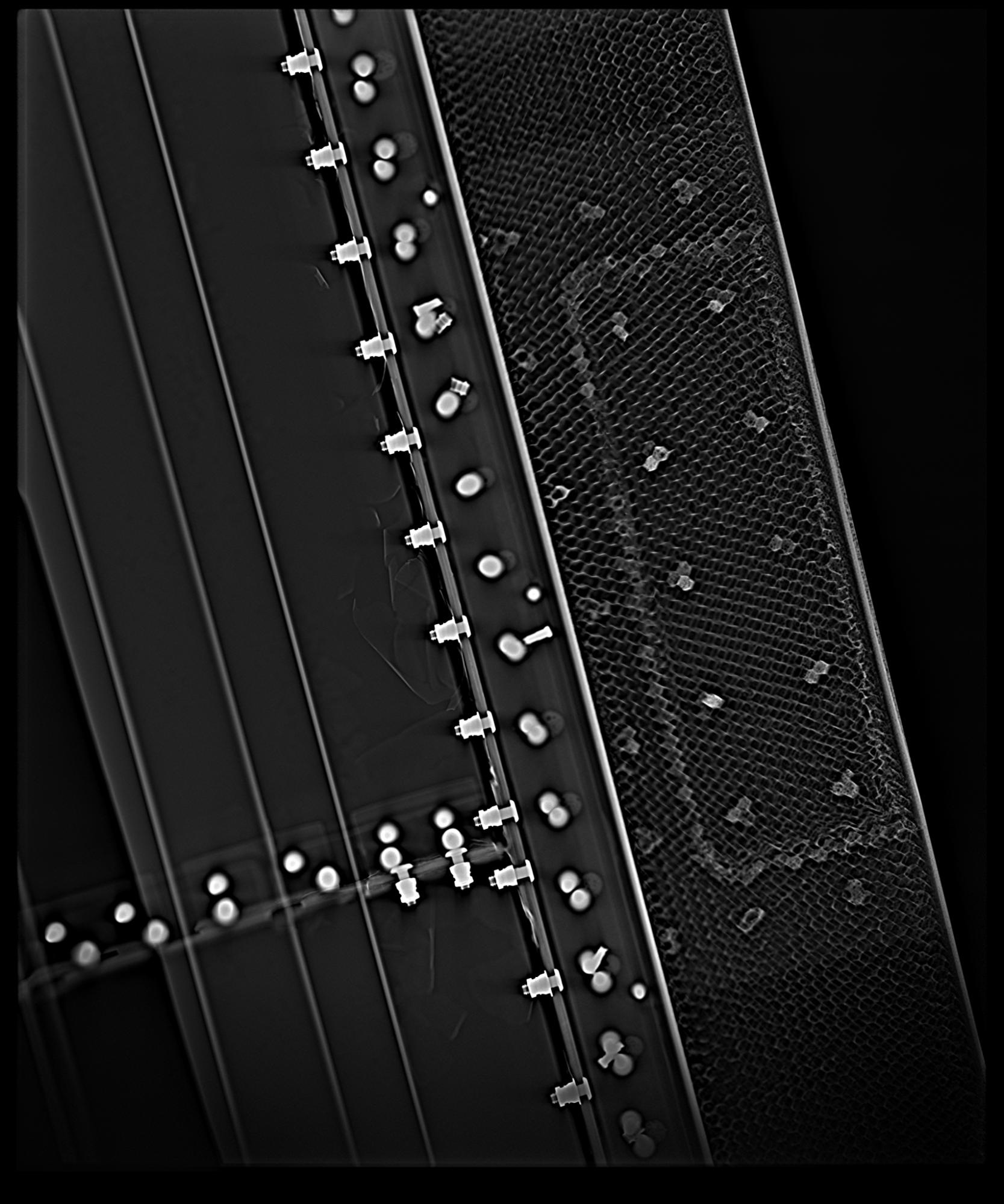

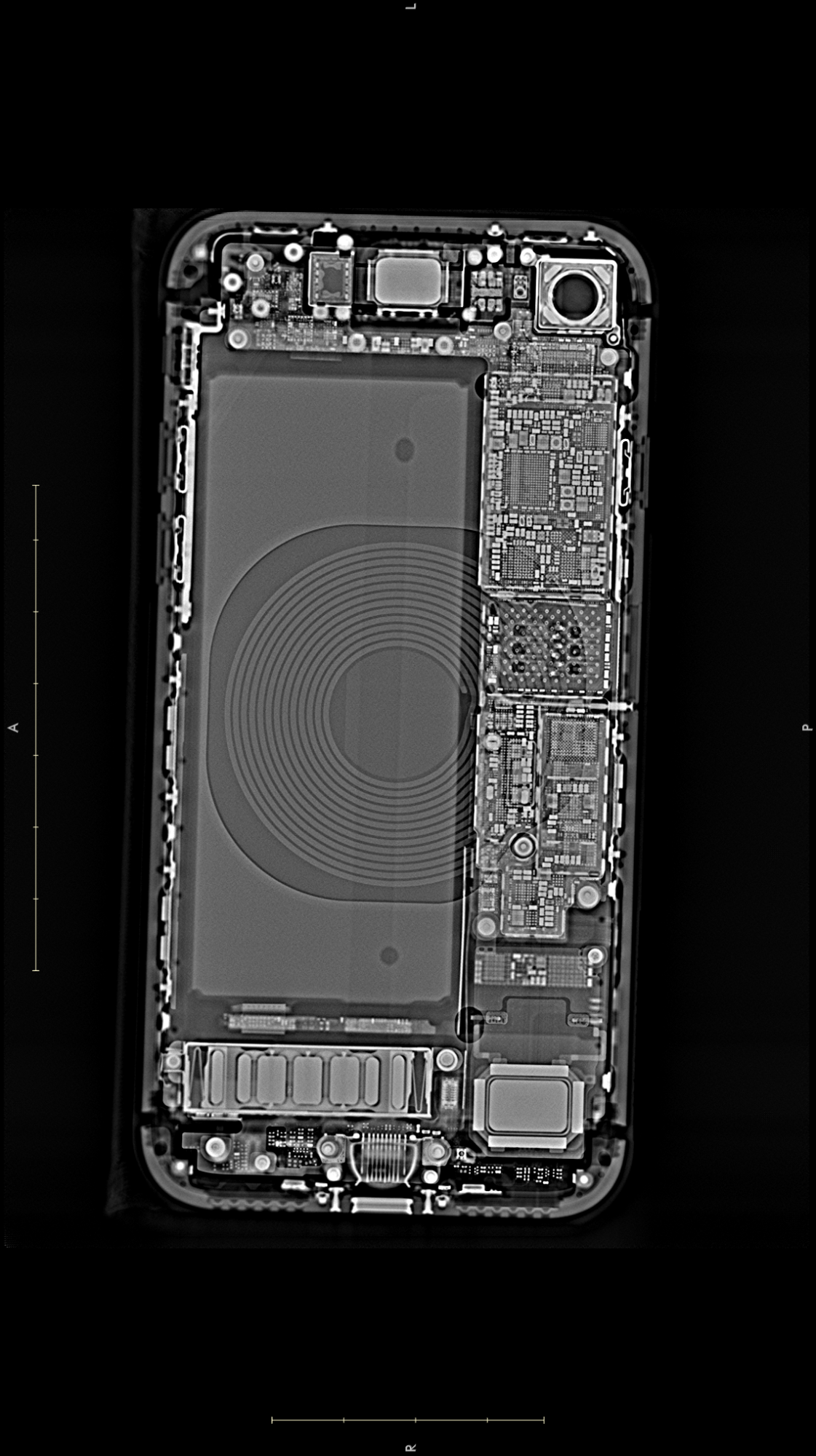

Place the caption here

Place the caption here

Place the caption here

Place the caption here

NDT Feasibility Studies.

Adaptix NDT3D offer an imaging service for feasibility studies for those customers who would like to develop an in-house NDT function utilizing the latest 3D imaging technology.

Partnering with your organization to develop the perfect solution for your NDT requirements, our team of Scientists and Engineers will work with you to understand your current challenges and identify the best method and machine for your individual requirements.

Available from individual day work packages for initial studies, to large scale projects, we offer flexibility to accommodate your needs.

Contact us today to discover how NDT3D can benefit your operations.

Discover how AdaptixNDT is transforming NDT with fast, portable 3D X-ray inspection.

Explore our solutions and see how digital tomosynthesis can accelerate your diagnostics and support NDE4.0.

Adaptix are proud members of.